In July, The Neosho Daily News in Missouri featured a modular house put together by students in building trades classes at Crowder College.

[The] house was built modular style so it can be moved easily.

The only details we could find:

Interesting to note:

They held an open house and accepted "bids for the house with the winning bid subject to approval by the board of trustees."

The February 2009 issue of Dwell Magazine featured a modular home in Lost River, Virginia.

Worth a look: slideshow of 7 pictures.

Note: The house was built in 2007 - 2008. The owners tracked the entire process via their blog: A PreFab Project. Check out our related posts for more information.

Hat tip: Apartment Therapy on August 7, 2009.

A month ago, The Saratogian featured this 3-unit modular home in Saratoga Springs, NY.

According to owner, Helena Frost:

This is totally custom made in the factory...It really helped cut down on the cost, about $40 less per square foot.

See our earlier post for more details.

Marmol Radziner Prefab recently announced that

Marmol Radziner Prefab recently announced that  Haven Custom Homes will manufacture their

Haven Custom Homes will manufacture their  Skyline series of homes.

Skyline series of homes.

Todd Jerry, COO of Marmol Radziner Prefab:

We are excited to have found Haven Custom Homes and to partner with them on this exciting venture. The firm's commitment to the highest standards of green construction is impressive.

Jerry Smalley, CEO and president of Haven Custom Homes:

Haven is honored to partner with Marmol Radziner...We're excited to be able to bring their award-winning designs to the East Coast.

In the mail from Hayden Lindley (President):  ClearSpace Modular Homes, Inc. recently launched a line of prefab homes. Delivery is only available in Texas right now.

ClearSpace Modular Homes, Inc. recently launched a line of prefab homes. Delivery is only available in Texas right now.

According to their site:

We offer affordable, high-quality modern prefab housing that is sustainably focused and inspired by mid-century modern architectural design.

| Model | Size | BR | Bath |

|---|---|---|---|

The Casita The Casita |

432 sf | studio | 1 |

ShedSpace ShedSpace |

1,203 sf | 3 | 2 |

DualSpace DualSpace |

1,330 sf | 3 | 2 |

CenterSpace CenterSpace |

1,524 sf | 3 | 2 |

Two additional models are planned: CabinSpace and CornerSpace.

The pricing for base modules is listed as $110-$115 sf, but they estimate a building cost of $130-145 sf for one of their stock designs.

ClearSpace is hoping to start their first project soon and will post progress via their blog.

The houses are designed by Mark Meyer of designSTUDIO. He blogged about The Casita in March.

All American Homes recently kicked off The Living Zero Home Tour in conjunction with the U.S. Department of Energy.

All American Homes recently kicked off The Living Zero Home Tour in conjunction with the U.S. Department of Energy.

- Traveling home features interactive and educational displays designed to be informative and fun

- Purpose is to showcase energy efficient, commercially available products to hundreds of thousands of consumers

The tour began in Chicago on July 1, 2009. It will travel to 15 locations (PDF) through the end of November.

The company has a page describing some of the benefits of systems-built (modular) housing:

Each custom-built home is made ... in a controlled environment. Your home is protected from weather and vandalism during the construction process. It arrives to your site about 70 to 85% complete, and in most cases is set on its permanent foundation and locked the same day.

... controlled construction saves time and money. Systems-built home construction allows you to plan, predict and control costs through better scheduling and more accurate planning.

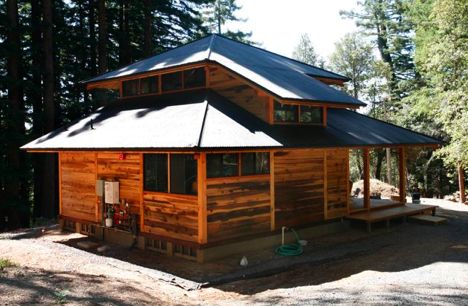

New World Home produces "a line of new homes based upon historically inspired designs" called A New Old Green Modular™ (NOGM).

New World Home produces "a line of new homes based upon historically inspired designs" called A New Old Green Modular™ (NOGM).

The homes combine a very traditional look with a modern approach:

... constructed with environmentally sanctioned products and practices, and are factory-built in a state-of-the-art, highly efficient manufacturing facility.

... can be produced, transported, erected and finished in 60-90 days from the time the production process is initiated.

Prices range from approximately $115-$180/sf.

They offer 7 models:

| Model | Size | BR | Bath |

|---|---|---|---|

Walden Cottage Walden Cottage |

471 sf | 1 | 1 |

Emerson Emerson |

1,749 sf | 3 | 2.5 |

Carson Carson |

1,775 sf | 3 | 2.5 |

Carver Carver |

2,267 sf | 3 | 2.5 |

Carson w/Addition Carson w/Addition |

2,319 sf | 4 | 2.5 |

Buckminster Buckminster |

2,332 sf | 3 | 2.5 |

Chadwick Chadwick |

2,573 sf | 3 | 2.5 |

Check out their promotional video (1:47).

Hat tip: Jetson Green on July 1, 2009.

LivingHomes recently posted renderings of a Ray Kappe modular home. The multifamily house will be built in Los Altos, CA.

LivingHomes recently posted renderings of a Ray Kappe modular home. The multifamily house will be built in Los Altos, CA.

Size: 3,864 sf with 3 units:

- two: 3 BR, 3 bath

- one: 1 BR, 1 bath

More details from the comments section:

One unit will be owner-occupied, one will be low-income, and one will be a standard rental.

Worth a look: their new Tour/Gallery page with virtual tours, videos and photos.

LABhaus recently announced a new product line designed for restrictive inner city lots.

LABhaus recently announced a new product line designed for restrictive inner city lots.

The inFill line will offer homes ranging from approximately 1,124 sq ft to 3,108 sq ft and turn-key MSRP pricing ranging [from] $149,900 to $379,900.

They offered a preview of one model:

Check out the post for more images.

Keiser Homes manufactures custom modular homes in Maine, for delivery there and in New Hampshire, Vermont, Massachusetts, Connecticut, and Rhode Island.

Keiser Homes manufactures custom modular homes in Maine, for delivery there and in New Hampshire, Vermont, Massachusetts, Connecticut, and Rhode Island.

From their site:

Inside an 80,000 square foot facility, we use a system developed to control every step of the building process.

...

Because Keiser Homes is a wholesaler that sells through builders, we cannot give out pricing. We can however, tell you that our pricing is comparable to stick built homes.

They offer a wide variety of models ranging from 840 - 3,120 sf with 1-4 bedrooms. (Follow the above link for a complete list.)

Also, check out:

On her blog, Michelle Kaufmann shared pictures of a project designed by MKD prior to closing.

See the post for more pictures.

Marmol Radziner Prefab recently debuted their new Skyline Series at Dwell on Design. The homes are part of the Dwell Homes Collection.

Marmol Radziner Prefab recently debuted their new Skyline Series at Dwell on Design. The homes are part of the Dwell Homes Collection.

The Skyline Series is a mix and match system of four floor plans that create six unique homes designed for typical urban lots. Available in a range of configurations for one and two story homes. The Skyline series offers high end modern design, eliminates custom design fees and offers the benefits of prefab construction.

| Model | Price | Size | BR | Bath |

|---|---|---|---|---|

Skyline 1.2 Skyline 1.2 |

$550,000 - $750,000 | 1,318 sf | 2 | 1 |

Skyline 1.3 Skyline 1.3 |

$600,000 - $800,000 | 1,562 sf | 3 | 2 |

Skyline 2.3 Skyline 2.3 |

$750,000 - $950,000 | 1,925 sf | 3 | 2 |

Skyline 2.4 Skyline 2.4 |

$800,000 - $1M | 2,170 sf | 4 | 3 |

Skyline 2.5 Skyline 2.5 |

$800,000 - $1M | 2,542 sf | 5 | 3 |

Skyline 2.6 Skyline 2.6 |

$850,000 - $1,050,000 | 2,785 sf | 6 | 4 |

Hat tip: Inhabitat on June 29, 2009.

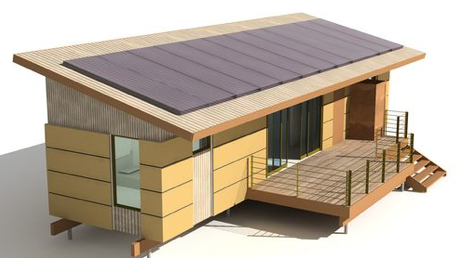

While researching yesterday's post about  Modular 3, we noticed more prefab projects by

Modular 3, we noticed more prefab projects by  Studio 804 at the University of Kansas School of Architecture and Urban Planning. Students in the program have used prefab since 2004.

Studio 804 at the University of Kansas School of Architecture and Urban Planning. Students in the program have used prefab since 2004.

In an effort to work as expeditiously as possible, we employ methods of prefabrication, building in modular units in Lawrence and shipping the final product to its final destination. This process limits construction waste, requires unique design solutions, and most importantly, allows students to continue to live in Lawrence throughout the process.

Interesting to note:

All aspects of the building process, with the exception of the licensed trades (electric, plumbing, and heating/air conditioning), are carried out by the students over the course of a single semester. This includes everything from initial design to finished construction and documentation.

| Model | Size | BR | Bath | modules | Year |

|---|---|---|---|---|---|

Modular 1 Modular 1 |

1,200 sf | 2 | 1 | 5 | 2004 |

Modular 2 Modular 2 |

1,200 sf | 2 | 1 | 6 | 2005 |

Modular 3 Modular 3 |

1,200 sf | 2 | 1 | 6 | 2006 |

Modular 4 Modular 4 |

1,500 sf | 2 | 1 | 7 | 2007 |

Check out the projects page on their site and click through each for more pictures.

We missed this article last fall. Natural Home Magazine featured a prefab home designed and built by students in the Studio 804 program at the University of Kansas School of Architecture and Urban Planning.

built in six modular units in nearby Lawrence, Kansas, where the Studio 804 program is based, then trucked 40 miles to Kansas City and assembled

The students designed and built the home over the course of five months.

Check out the photo gallery and video (3:07).

Hat tip: Low Impact Living Blog on June 22, 2009.

Not mentioned in the article or post: the house was built back in 2006.

Epoch Homes issued a press release back in May announcing their new Eco Collection.

Epoch Homes issued a press release back in May announcing their new Eco Collection.

According to CEO John Ela:

Our design goal was to expand upon our custom designed homes by offering some value engineered green homes that are lower cost to purchase and operate, while still offering a healthy lifestyle and resource efficiency.

Worth noting:

Epoch became the first modular home manufacturer in the nation to be certified under the Modular Green Approved program now offered by the NAHB Research Center

They are offering 10 models:

| Model | Size | BR | Bath |

|---|---|---|---|

Ecomod Butterfly Ecomod Butterfly |

768 sf | 1-2 | 1 |

Ecomod Gabled Ecomod Gabled |

768 sf | 1-2 | 1 |

Ecomod Tiered Ecomod Tiered |

768 sf | 1-2 | 1 |

Ecowood Ranch Ecowood Ranch |

1,344 sf | 3 | 2 |

Ecowald Ranch Ecowald Ranch |

1,400 sf | 3 | 2 |

Ecoberg Cape Ecoberg Cape |

1,610 sf | 2 | 1.5 |

Ecovale Cape Ecovale Cape |

1,860 sf | 2-3 | 2 |

Ecobrook Colonial Ecobrook Colonial |

2,016 sf | 3 | 2.5 |

Ecoleaf Colonial Ecoleaf Colonial |

2,352 sf | 3-4 | 2.5 |

Ecoplex Duplex Ecoplex Duplex |

2,464 sf | 4 | 4 |

We received an email from  LivingHomes with a link to their useful overview page. Here are their summaries with links to our updated model pages:

LivingHomes with a link to their useful overview page. Here are their summaries with links to our updated model pages:

Ray Kappe LivingHomes: LivingHomes by Ray Kappe are the epitome of warm, modern, sustainable living. Each RK LivingHome features floor-to-ceiling glass windows and doors to create a superior indoor/outdoor environment.

Ray Kappe LivingHomes: LivingHomes by Ray Kappe are the epitome of warm, modern, sustainable living. Each RK LivingHome features floor-to-ceiling glass windows and doors to create a superior indoor/outdoor environment.

KieranTimberlake LivingHomes: Our most affordable LivingHomes, the KT line are designed to fit on small, urban lots. The use of decking and light corridors provide outdoor space and natural, indoor light even in the most dense of urban environments. Rooms and entire floors can be added as your living needs change.

KieranTimberlake LivingHomes: Our most affordable LivingHomes, the KT line are designed to fit on small, urban lots. The use of decking and light corridors provide outdoor space and natural, indoor light even in the most dense of urban environments. Rooms and entire floors can be added as your living needs change.

FKDA Architects designs and builds micro-homes in the UK.

FKDA Architects designs and builds micro-homes in the UK.

They currently offer two models they call "sheds":

According to their site:

The shed could be entirely prefabricated in a factory and delivered to site

...

Alternatively, the components can be delivered and the shed assembled on site, with each being small and light enough for one or two people to manhandle, eliminating the need for a crane.

...

The total process typically takes around 18 weeks.

They are also working on a Zero Carbon modular house they are calling eco-home. We will post more information when it becomes available.

Hat tip: Inhabitat on June 16, 2009 via Design Boom on June 15, 2009.

GOOD Magazine recently highlighted the design company  Project FROG. They are creating modular units as alternatives to the trailers now in use at public schools in California.

Project FROG. They are creating modular units as alternatives to the trailers now in use at public schools in California.

According to Adam Tibbs, president of Project Frog:

[My] goal is to replace all of California’s portable classrooms with green buildings by 2015.

There are currently around 85,000 trailers throughout the state.

Unlike trailers, FROG classrooms are made from prefabricated modular units, and can be arranged in different sizes and shapes to fit each school’s needs.

Read the entire article for more details.

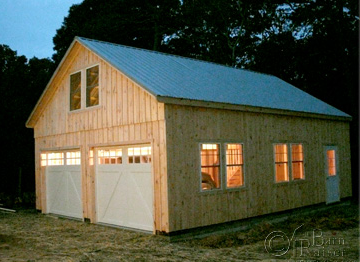

Tiny House Blog recently covered a company in Saugerties, NY that sells prefab and modular structures made by Amish craftsmen. See the post for information sent in by the owner, Dave Ortlieb.

Structures by  The Barn Raiser include:

The Barn Raiser include:

- storage sheds and barns

- 1-and 2-car garages

- 2-story buildings

- gazebos

- horse barns

From the FAQ area on their website:

buildings are pre-fabricated and they come completely assembled, except for the double-wide, 2-story & 2-car garage which arrive in 2 halves

Delivery of the structures averages 4 weeks.

See their price list and view their photo gallery.

Hat tip: materialicious on June 10, 2009.

Matthew Grace Architecture in Australia now offers four resPOD prefab homes.

Matthew Grace Architecture in Australia now offers four resPOD prefab homes.

According to their site, resPOD is:

an extremely cost effective modular form of flexible living that enables every homeowner to be environmentally responsible and sustainable whilst maintaining a high level of quality and detail.

All models are constructed from steel shipping containers.

| Model | Size | BR | Bath | Stories |

|---|---|---|---|---|

A-Type A-Type |

291 sf (27 m²) |

1 | 1 | 1 |

B-Type B-Type |

603 sf (56 m²) |

2 | 1 | 1 |

C-Type C-Type |

1,120 sf (104 m²) |

3 | 1 | 2 |

D-Type D-Type |

1,668 sf (155 m²) |

4 | 2 | 3 |

(We were unable to find pricing information.)

Hat tip: Inhabitat on May 25, 2009.

Simpatico Homes will begin building their first prefabricated home in Emeryville, CA this summer.

Simpatico Homes will begin building their first prefabricated home in Emeryville, CA this summer.

Follow their progress via twitter and/or their blog.

Hat tip: Jetson Green on June 2, 2009.

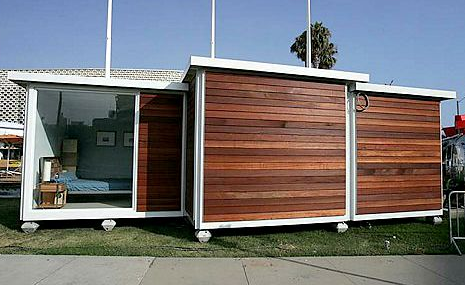

Modular Dwellings, led by Edgar Blazona, creates "mobile, modern and affordable buildings."

Modular Dwellings, led by Edgar Blazona, creates "mobile, modern and affordable buildings."

| Model | Size | BR | Bath | |

|---|---|---|---|---|

MD 42 MD 42 |

42 sf | 1 | 0 | |

MD 100 MD 100 |

100 sf | 1 | 0 | |

MD 120 MD 120 |

120 sf | 1 | 0 | |

MD 144 MD 144 |

144 sf | 1 | 0 | |

MD 280 MD 280 |

280 sf | 1 | 1 | |

(We were not able to find pricing information on their site.)

Hat tip: Coming Unmoored on May 22, 2009.

Haven Custom Homes recently issued a press release to announce the completion of a modular home in the Whisper Mountain community just outside of Asheville, NC.

Haven Custom Homes recently issued a press release to announce the completion of a modular home in the Whisper Mountain community just outside of Asheville, NC.

The home is one of four being offered within the 2009 Southern Living Choose Your Home Giveaway presented by MyHomeIdeas.com. (The contest ends on June 30, 2009.)

The contest website includes:

- pictures

- video (3:09)

- virtual tour

- floorplans

According to the press release, the house is open to the public for tours:

Viridis Homes in the UK offers 4 modular models:

Viridis Homes in the UK offers 4 modular models:

| Model | Price | Size | BR | Bath |

|---|---|---|---|---|

Bungalow Bungalow |

$132,867 (£83,203) |

898 sf (83.38 m²) |

2 | 1 |

Terraced Terraced |

$79,845 - $95,814 (£50,000 - £60,000) |

905 sf (84.11 m²) |

2 | 2 |

Semi-Detached Semi-Detached |

$130,472 (£81,703) |

905 sf (84.11 m²) |

2 | 2 |

Detached House Detached House |

$133,181 (£83,400) |

905 sf (84.11 m²) |

2 | 2 |

According to their site:

Our homes are manufactured under factory controlled conditions and are delivered complete with all internal and external finishes, ready for assembly. Unlike other modular buildings, our homes can be transported and installed without the need for expensive cranes. Once the homes have arrived onsite, they are assembled and connected to services quickly and easily within 48 hours by our own team of specialists.

Hat tip: Manchester Confidential Property on May 6, 2009.

We recently received an email from  ma, an offspring of

ma, an offspring of  KRDB in Austin, TX. From their site:

KRDB in Austin, TX. From their site:

When we were searching for a name for our new modern, modular company, we kept returning to the Japanese concept, ma, meaning an interval in time and space, a dramatic pause, the silence between phrases of music. In architecture it is a quiet, neutral space that enhances the whole of a design.

They currently offer 6 modules:

| Model | Size | BR | Bath |

|---|---|---|---|

dharma dharma |

540 sf | 0 | 1 |

karma karma |

540 sf | 0 | 1 |

intima intima |

540 sf | 2 | 1 |

maxima maxima |

900 sf | 0 | 1 |

grandma grandma |

900 sf | 1 | 1 |

soma soma |

900 sf | 2 | 2 |

More information:

Some news we missed in March:  Epoch Homes was nominated for a Small Business Association of New England (SBANE) Innovation Award for its Unique Green Design/Build System.

Epoch Homes was nominated for a Small Business Association of New England (SBANE) Innovation Award for its Unique Green Design/Build System.

Interesting to note:

Epoch became the first modular home manufacturer in the nation to be certified under the Modular Green Approved program now offered by the NAHB Research Center, which administers the National Green Building Certification program for residential construction.

Hat tip: Building Systems on March 27, 2009.

Jetson Green recently covered a pilot project in Washington state.

With the sponsorship of the Seattle Archidiocesan Housing Authority and a grant from Enterprise Community Partners, Mithun designed three prefabricated modules to provide a model for affordable housing for farmworkers and their families.

Each of the 3 module designs by  Mithun are 580 sf.

Mithun are 580 sf.

Two of the first constructed units will go to farms in Skagit Valley, while the other will likely end up in Yakima. Upon completion, the homes will be publicly available by appointment.

Check out the post for more pictures and see Mithun's project detail page for further information.

We didn't see any information on costs, so it's not clear if the "affordable" part of the goal was met.

Haven Custom Homes recently issued a press release announcing their receipt of the 2009 Modular Multi Family Award from the National Modular Housing Council (NMHC). The award was given for the design "The Alcott".

Haven Custom Homes recently issued a press release announcing their receipt of the 2009 Modular Multi Family Award from the National Modular Housing Council (NMHC). The award was given for the design "The Alcott".

The Alcott is part of a new townhome project scheduled to be built this summer at Mt. Washington Resort in Bretton Woods, New Hampshire.

Model details:

Check out the architect's renderings.

The awards are co-sponsored by the Manufactured Housing Institute (MHI) which has a complete list of winners.

Hat tip: Maryland Gazette on May 6, 2009.

Northland's NewsCenter in Duluth, MN recently featured the setting of a modular home manufactured by  Dynamic Homes and installed by

Dynamic Homes and installed by  Ideal Homes.

Ideal Homes.

See the post for a multimedia version of the story (2:11).

Epoch Homes will be conducting factory tours this weekend.

Epoch Homes will be conducting factory tours this weekend.

Details:

If you can't make it to their factory, check out their video tour. (3:18)

The Vancouver Sun recently featured an interesting proposal by architect George Henriquez (of  Henriquez Partners Architects) and real estate consultant Michael Geller.

Henriquez Partners Architects) and real estate consultant Michael Geller.

Vancouver city council is backing a proposal to provide 550 temporary housing units for the homeless, including prefabricated modular units

According to Geller:

capital costs would vary between $37,000 and $46,000 per unit, compared to $302,000 for permanent units already announced by the province

Read the article for more details.

Hat tip: PropertyProf Blog on April 16, 2009.

All American Homes recently issued a press release to announce their pilot project with the Boulder County Housing Authority.

All American Homes recently issued a press release to announce their pilot project with the Boulder County Housing Authority.

The goal:

... to create one, affordable, near zero energy duplex and one single family ranch ...[using] leading-edge technology and modular construction practices.

...

It is expected that the homes will be delivered to the Lafayette, Colorado site in late April 2009, and be ready for occupancy by the end of June.

Hat tip: Building Systems on April 10, 2009.

The Herald Sun in Australia reports that the first re-Growth pod by  1:1 Architects has arrived on site.

1:1 Architects has arrived on site.

They are available at a cost of $30,000, and can be built as single or multiple units and placed on almost any block in two weeks.

Read the entire article for more details.

Hat tip: Arch Daily on April 12, 2009 and the re-Growth pod blog on April 8. Both include pictures.

LABHaus offers modern modular homes that can be ordered and delivered within 120 days.

| Model | Price | Size | BR | Bath |

|---|---|---|---|---|

Slide Slide |

$199,900-$224,400 | 1,464 sf | 3 | 2.5 |

Stretch Stretch |

$299,900-$324,900 | 2,243 sf | 3 | 2.5 |

ecoVilla ecoVilla |

$599,900-$649,900 | 4,551 sf | 5 | 4.5 |

Check out 32 factory tour photos from Indiana Building Systems.

See additional thoughts at Jetson Green from April 12, 2009.

On her blog, Michelle Kaufmann recently shared pictures of an  MKD custom designed home in California.

MKD custom designed home in California.

The pictures show

the stunning mixture of the Cor-ten weathering steel [roof] ... and cedar plank siding

From MKD's site:

In addition to our current design offerings, we offer Custom Design services. We design unique solutions for unique sites. Our experience with off-site modular technology, sustainable materials, and smart design techniques allows us to craft beautiful, sustainable homes to suit individual tastes and varying landscapes.

Haven Custom Homes recently issued a press release to announce completion of their first home at

Haven Custom Homes recently issued a press release to announce completion of their first home at  Sanctuary Communities in North Carolina.

Sanctuary Communities in North Carolina.

The home was delivered to the site ... nearly 80 percent complete.

...

The neighborhood is designed to reflect neighborhoods of America's past and be a walkable, mixed-use village when completed.

Also available in 2009:

| Model | Size | BR | Bath | |

|---|---|---|---|---|

Cowee Creek II Cowee Creek II |

1,002 sf | 1 | 2 | |

Cowee Creek I Cowee Creek I |

1,496 sf | 2 | 3 | |

The Windy Gap The Windy Gap |

1,343 sf | 2 | 3 | |

The Cullowhee The Cullowhee |

1,879 sf | 3 | 4 | |

The Redlands The Redlands |

2,598 sf | 3 | 4 | |

Hat tip: Building Systems Blog on March 24, 2009.

Read our earlier post for more details on the development, and the role of modular.

Live Edge in West Oakland, CA has an interesting source of wood:

Live Edge in West Oakland, CA has an interesting source of wood:

LE uses urban trees which are removed for many reasons: disease, storm damage, danger of falling, or to clear the way for a construction project. We regularly accept usable raw logs from local arborists and salvage some of these trees.

The company builds furniture and prefab houses.

The building process is based on an 8ft. modular plan...The kit is comprised of posts, beams, floor panels, wall panels, doors, roof and ceiling components. It is a finite set of parts which can be arranged in an infinite number of ways. Live Edge produces all the parts for a kit home in our shop, adapted to each design, to be assembled on site.

Check out their picture gallery.

Hat tips: Apartment Therapy on March 26, 2009 and Jetson Green on March 27, 2009.

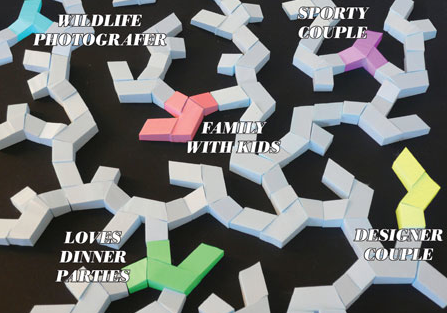

Stillwater Dwellings offers a cool "mix and match" approach with their interchangeable series:

Stillwater Dwellings offers a cool "mix and match" approach with their interchangeable series:

It’s as easy as A-B-C: start with your favorite Living Module (A.). Add a Connector Module (B), then complete your design by attaching your desired Bedroom Module (C). Its as easy as that! Each module is designed with a universal connector location so they all fit together. You can arrange them in any A-B-C combination you want.

The company will complete its first home in June 2009 in Bend, Oregon. Some background from their site:

We founded Stillwater Dwellings on one primary principle: Quality, prefabricated homes do not need to be expensive.

...

All of our homes are built off-site, in state-of-the-art manufacturing facilities. These facilities are climate controlled, and use a consistent, high-caliber workforce of carpenters and tradesmen.

...

From first contact with us to final cleaning, your home can be "move in" ready in about 3-4 months

They also have a set of fixed models:

| Model | Price | Size | BR | Bath | Stories |

|---|---|---|---|---|---|

miniONE miniONE |

$49,950-$89,000 | 370 sf | studio | 1 | 1 |

miniTWO miniTWO |

$79,500-$117,000 | 585 sf | 1 | 1 | 1 |

sd111 sd111 |

$113,100-$169,650 | 870 sf | 1 | 1 | 1 |

sd112 sd112 |

$117,000-$175,500 | 900 sf | 2 | 1 | 1 |

sd121 sd121 |

$130,000-$195,000 | 1,000 sf | 2 | 1 | 1 |

sd122 sd122 |

$162,500-$243,750 | 1,250 sf | 3 | 2 | 1 |

sd123 sd123 |

$199,950-$302,250 | 1,550 sf | 3 | 2 | 1 |

sd131 sd131 |

$214,500-$321,750 | 1,650 sf | 2 | 3 | 1 |

sd132 sd132 |

$260,000-$390,000 | 2,000 sf | 3 | 3 | 1 |

sd133 sd133 |

$299,950-$441,750 | 2,325 sf | 3 | 3 | 1 |

sd211 sd211 |

$253,500-$380,250 | 1,950 sf | 3 | 3 | 2 |

sd212 sd212 |

$227,500-$332,500 | 1,750 sf | 4 | 3 | 2 |

sd221 sd221 |

$344,500-$503,500 | 2,650 sf | 3 | 3 | 2 |

sd222 sd222 |

$390,000-$570,000 | 2,990 sf | 3 | 3 | 2 |

sd231 sd231 |

$383,000-$560,500 | 2,950 sf | 3 | 3 | 2 |

Hat tip: Jetson Green on March 25, 2009.

Construction is about to begin on the Aria Denver project by  Michelle Kaufmann Designs.

Michelle Kaufmann Designs.

From Ms. Kaufmann's blog:

The construction contract for Phase 1 of the Colorado-based multifamily community project we’ve designed, called ariaDenver, has officially been signed!

...

it embodies many of our core beliefs about community in terms of sustainable design, off-site construction techniques, and diversity.

...

Phase 1 includes 8 homes, and an additional 106 townhouse homes are planned for the following phases, with a mix of 2- and 3-stories, live/work, market rate and affordable green homes.

For other renderings, see her post dated October 16, 2008.

The Contemporist recently covered a two-family prefab in Austin, TX.

According to the architect's website:

The house is constructed of a modular steel frame. The frame is infilled with prefab thermasteel panels to minimize construction on-site waste. The structural frame is exposed, showing the construction process and articulating the house’s facades. The repetitive modular method, as well as the prefabrication allowed for greater efficiency during construction.

Check out:

- pictures ... though the Contemporist post has a nice selection that loads faster

- virtual tour

- Chinese magazine article in Vision May 2007 (PDF)

We also found a video (2:00) showing some of the construction details.

We received an email a while back from  GreenPod Development.

GreenPod Development.

From their site:

GreenPods are compact custom modular homes built for energy efficiency, indoor air quality, and sustainability. From foundation to roof, inside and out, Pods can be individually customized and furnished to your specifications and individual living style.

They have a complete line of models called soloPODS:

| Model | Price | Size | BR | Bath |

|---|---|---|---|---|

Lopez Lopez |

$60,000 | 372 sf | 1 | 1 |

Port Townsend Port Townsend |

$85,000 | 420 sf | 1 | 1 |

Lummi Lummi |

$85,000 | 553 sf | 1 | 1 |

Bainbridge Bainbridge |

$85,000-$165,000 | 630 sf | 1 | 1 |

Mercer Mercer |

? | 648 sf | 1 | 1 |

Ludlow Ludlow |

$95,000 | 731 sf | 1 | 1 |

Camano Camano |

$125,000 | 731 sf | 1 | 1 |

Langley Langley |

$150,000 | 731 sf | 1 | 1 |

Quil Quil |

? | 731 sf | 1 | 1 |

Winslow Suspended Winslow Suspended |

? | 731 sf | 1 | 1 |

Orcas Orcas |

$175,000 | 744 sf | 1 | 1 |

Additional information:

- steps to purchase and build

- costs (hard and soft)

- specifications

- service areas

- joining and stacking pods

- floating pods

The News & Observer in North Carolina highlighted a modular hybrid home.

Studio B adapted the prefabricated portions of the house into a simple, striking composition: modules on the ends, a recessed entry space in the middle and a single sloped roof capping it all. Three parts of the house were trucked to the site from a nearby factory and installed in one day.

...

Spanning the prefabricated modules...is the portion of the project that was built on site: the two-story living area

We found model information on the BuildSense website:

They also share a floorplan (PDF) that includes a series of construction pictures.

Read the entire News & Observer article for more information and check out their photo gallery.

Arch Daily recently covered Villa Grow from Sweden:

villas have a common basic unit that can be extended by adding new modules. The angles at the end of each unit allow for different orientations, on which you can have a linear house, a patio house, or an organic layout that opens to the landscape.

More information:

Check out their promotional video. (3:59)

The April 2009 issue of Metropolitan Home features the first  PLACE House built by

PLACE House built by

PLACE Architects in Kirkland, Washington.

PLACE Architects in Kirkland, Washington.

the PLACE house was erected on-site using SIPs

We found model information on their website:

| Model | Size | BR | Bath |

|---|---|---|---|

tiny tiny |

935 sf | 1 | 2 |

small small |

1,247 sf | 2 | 3 |

medium medium |

1,669 sf | 3 | 3 |

large large |

2,091 sf | 3 | 3 |

They offer three different style packages:

- urban (PDF)

- naturalist (PDF)

- vanguard (PDF)

Also, check out pictures of the first PLACE House being constructed.

Read the entire Metropolitan Home article.

(Hat tips: Apartment Therapy on March 13, 2009 and Jetson Green on March 17, 2009.)

NY Daily news recently covered a prefab housing development in East New York.

Details:

-

designer:

Alexander Gorlin Architects

Alexander Gorlin Architects

-

builder:

Capsys Corp.

Capsys Corp.

- developer: Nehemiah Housing Development Fund

- price: $158,000 - $350,000

- plan: over 550 homes by 2013

The Nehemiah houses in the Spring Creek development are being assembled

in a Brooklyn Naval Yard factory as big as a football field

where construction workers

churn out more than 8,000 square-feet per week on a supersized assembly line for homes. Working in three separate areas, men build ceilings, flooring and wall frames. Cement trucks pour concrete floors while blast machinists drill holes for pipes and wiring. Then, the three components merge as the homes take shape. Beams are established, paint is applied, and toilets are installed.

After tying down any loose parts such as kitchen drawers and oven doors, the 20-by-40 units are shipped by extra-wide flatbed trucks to the East New York site.

On site, a 250-ton hydraulic truck crane lifts the units on top of each other to build the two-, three- and four-story homes.

Worth noting:

Founded in the mid-1980s by powerful local preachers as a means to rebuild East New York, the Nehemiah Housing Development Fund Co. is the real estate arm of East Brooklyn Congregations. In 20 years, they built and sold more than 3,000 homes with a foreclosure rate of less than 1%.

Read the entire article for more information, and see pictures of the units on the Capsys website.

ideabox recently finished moving their

ideabox recently finished moving their  confluence prefab from the 2009 Portland Home & Garden Show to a neighborhood in Port Townsend, WA.

confluence prefab from the 2009 Portland Home & Garden Show to a neighborhood in Port Townsend, WA.

Realtor Charlie Arthur of RE/MAX FIRST, INC. is blogging about the house:

This unit is going to be our model unit for the presales...We will be offering 2 and 3 bedroom homes for in the low 200's

Scroll through his recent posts for more details, e.g.

If you find yourself in the area, check out their upcoming Open House:

Hat tip: Jetson Green on February 18, 2009.

Low Impact Living recently featured a company called  Eco Structures in West Virginia.

Eco Structures in West Virginia.

Eco Structures is the brainchild of John Garlow, who has been building timber frame homes and using structural insulated panels (SIPS) out of his own workshop since the late 1970s. Several years ago, when it became clear that the green prefab housing market was ripe for liftoff, he decided to put his many years of prefabrication expertise to use with a new “green” twist. He designed and built a prototype modular Eco Structure on his own property and a new company was born.

...

The target price ... is approximately $150 - $175 per square foot.

Additional information:

- 50+ pictures of construction

- video coverage from West Virginia Public Broadcasting, dated April 10, 2008 (7:41) and July 3, 2008 (8:08)

- customized options drawings

- sample price breakdown

The Baltimore Sun reprinted a McClatchy-Tribune article about The Pennywise House.

It's part consciousness-raising effort and part marketing campaign for his house plans and a coming line of modular homes that will be based on them.

...

The houses ... [will] be based on the vernacular architecture of 10 regions of the country, which he thinks will help bring character to their environs.

...

He hopes his "Pennywise House" proposal will draw attention to the benefits of returning to those traditional architectural styles, with updates to make them livable today. Those styles developed and became popular because they were adapted to the local conditions, he said - deep porches in the hot South, for example, and piers in South Carolina's Low Country to raise the houses above the moist ground.

Here are the details of "The Simple Cottage Sampler" line:

-

designer:

Russell Versaci

Russell Versaci

-

builder:

Haven Custom Homes

Haven Custom Homes

- size: 400 - 950 sf (can be expanded with additional modular units)

- availability: on the east coast (US) later this year

- price: has not been set

- view designs (PDF)

Read the entire article.

(Hat tip: Building Systems on March 9, 2009.)

Method Homes recently introduced their Balance S-M-L Series.

Method Homes recently introduced their Balance S-M-L Series.

According to their website, they are:

highly efficient prefab homes, with small footprints to boot ... designed to arrive 95% complete within 2-3 months of purchase.

Individual model prices are not listed, but they mention the line will be "starting under $100,000".

Here's the model information:

| Model | Size | BR | Bath |

|---|---|---|---|

Small Small |

565 sf | 0 | 1 |

Medium Medium |

744 sf | 1 | 1 |

Large Large |

992 sf | 1-2 | 1 |

To see the layouts:

- Small floorplan (PDF)

- Medium floorplan (PDF)

- Large floorplan (PDF)

The series was created in collaboration with  Balance Associates.

Balance Associates.

Hat tip: Jetson Green on March 11, 2009.

In the news: the re-Growth Pod from  1:1 Architects in Australia. According to their website, it's:

1:1 Architects in Australia. According to their website, it's:

A completely self contained concrete service pod. It is a permanent and cost effective housing unit which can assist in the rebuilding of the fire devastated town-ships of Victoria.

The robust pre-fabricated concrete structure has been designed to be built upon, but in the short term acts as a habitable starting point for the building of a new home. The units can be prefabricated, delivered and connected to services rapidly allowing families to begin the process of re-building without displacement from their communities.

Watch the assembly animation video (0:20).

The prototype will be built by  Ecotec Build Solutions. Track their progress via the re-Growth Pod blog.

Ecotec Build Solutions. Track their progress via the re-Growth Pod blog.

Hat tips: Arch Daily on March 4, 2009 and Treehugger on March 6, 2009.

Last week, Times Union covered a new 3-unit prefab building in Saratoga Springs, NY.

Highlights:

-

builder:

Westchester Modular Homes

Westchester Modular Homes

- designer: Phinney Design Group

- 4,200 sf, 2 stories

- the sections arrived in six boxes

- "saved 20 percent on building and loan costs by going prefab"

- built in 8 days in the factory (plus additional work to be done on site)

Over the next few months, workers will add custom porches, cupolas and other features to make the home fit into the area's Victorian streetscape

Read the entire article for details.

The New York Times recently discussed the sustainability of modular housing.

The modular housing industry likes to say that it has always had a few characteristics that today might be considered eco-friendly — from reduced waste to a smaller construction footprint.

But it’s only recently — and increasingly amid the flagging housing market — that manufacturers of factory-built homes have realized that concepts like efficiency and sustainability can make for good business strategy.

Mentioned in the article:

-

Ecohealth Homes Inspired by Caroline McKenna

Ecohealth Homes Inspired by Caroline McKenna

-

LivingHomes

LivingHomes

-

Michelle Kaufmann Designs

Michelle Kaufmann Designs

-

New World Home

New World Home

-

Penn Lyon Homes

Penn Lyon Homes

Read the entire article.

(Hat tip: Charles Bevier of Building Systems on February 11, 2009.)

The Cape Cod Times recently featured custom modular homes by  Realty Development Associates in Sagamore, MA.

Realty Development Associates in Sagamore, MA.

Modular home buyers now have a wide choice of fine features that rival those in stick-built homes, from tray and vaulted ceilings, to granite and marble tiles, carpet to wood flooring, maple or cherry cabinets, beadboard and paneled wainscoting and high-grade insulated windows.

Read the entire article for more details.

The New York Times recently featured a prefab house called the  BrightBuilt Barn.

BrightBuilt Barn.

According to the BrightBuilt Barn website:

BrightBuilt Barn, a project that pushes the envelope of sustainable design, is the practical outcome of an in-depth collaboration between a team of the Northeast’s top green professionals and builders, and a visionary client coming together to create a super-green, offsite fabricated, and beautiful Net-Zero building that can be replicated and adapted over time.

The details:

Follow the regularly updated blog to track the progress or check out the media kit (pdf) to see floorplans.

Other coverage around the web:

- Jetson Green on September 19, 2008 and December 30, 2008.

- Lloyd Alter at TreeHugger on December 30, 2008.

- Materialicious on January 12, 2009.

- Inhabitat on January 16, 2009.

For more details, read the entire article.

The 2009 International Builders' Show (IBS) will be in Las Vegas next week.

Owned and produced by the National Association of Home Builders (NAHB), IBS is the largest annual light construction show in the world.

Who should attend? According to their website:

suppliers and manufacturers looking to market and sell to builders, architects, developers, dealers, and distributors.

Of particular interest to Prefabcosm readers, the (modular) NextGen “Urban Living” Home, built by  Champion Genesis will be on display in the convention center parking lot.

Champion Genesis will be on display in the convention center parking lot.

Catching up on a backlog of old news. Here's a story out of Austin, Texas:

In about seven hours, Austin builder Gary Bellomy used a 100-foot-tall, 100-ton crane to erect a pair of townhomes that are expected to earn the top rating from Austin Energy's Green Building Program.

Not bad, considering a project this size would typically take months to build. The secret: modular construction.

Companies mentioned:

- Palm Harbor Homes

- Discovery Custom Homes

- Town Builders

- KRDB

Read the full article for details.

We just received an email from Ann Raab at  GreenPod Development:

GreenPod Development:

Our first GreenPod home, Franny’s Pod, named after its owner ... will be complete in a few days!

Members of the press, government officials, and the public are invited to tour Franny's new home, talk with GreenPod designers and staff, and learn more about sustainable living.

The Boston Herald recently reprinted an Associated Press article about a modular classroom built by Project Frog.

it's a demonstration of how modular construction can be used to construct green buildings cheaper, faster and better.

The classroom was built as a part of the Greenbuild International Conference & Expo which was in Boston last week.

Project Frog ... uses modular building to offer affordable enviro-friendliness — [Mark Miller, the company’s chief executive officer] says its buildings are 25 percent cheaper than traditional construction, though more expensive than normal modular buildings... "I think it’s a huge and neglected part of green building," said [Miller].

The article listed a number of advantages of modular construction, including:

- each piece of the home can be specially designed and fitted, using materials produced with the least environmental impact for maximum energy efficiency and health - each component — the kitchen, the wiring — can be tested for quality in a factory away from the wind and rain

But also recognized the many challenges: (some we agree with, others we don't)

- perception of being cheap and ugly

- Americans generally remain skeptical about the quality of buildings

- standardization can be a drawback ... because most people want to custom build

- limited by relatively few modular building producers

- difficulties transporting the sections to some tightly packed areas

- nature of the housing market, in which most people remodel existing homes, rather than build new ones

Miller is hopeful despite the current housing market:

I can almost guarantee you that at the end of this, green building will still be around, and will probably be kicking up even more, and modular will still be around and be kicking up even more.

Read the whole article for more details, including interviews with:

- Art Breitenstein of All-American Homes

- Carlos Martin of the National Association of Home Builders

Coverage of Project Frog on other blogs:

- Treehugger on November 20, 2008

- Jetson Green on November 22, 2008

We're still catching up on news from last month. Here's a story worth covering:

Homes for Our Troops is a non-profit organization that provides homes to military personnel with severe injuries or disabilities sustained in active-duty wartime. Tidewater Modular Homes of Virginia Beach teamed up with Nationwide to provide the house for Bartlett, which will be set on its foundation in Chesapeake on Veteran’s Day Nov. 11.

Bartlett, who lives in Norfolk, came to Martinsville on Wednesday for a reception at Nationwide. He toured his future home in progress, stepping through the rooms on a $110,000 pair of prosthetic legs.

His new modular home is 1,475 sf and handicapped-accessible.

Some links:

- more details

-

Tidewater Custom Modular Homes is the local builder

Tidewater Custom Modular Homes is the local builder

-

Nationwide Custom Homes in Martinsville, VA is a systems-built manufacturer

Nationwide Custom Homes in Martinsville, VA is a systems-built manufacturer

- Homes For Our Troops accepts donations

(Hat tip: Charles Bevier of Building Systems on October 24, 2008)

Here's an interesting modular development that was announced last month:

Haven Custom Homes ... and Sanctuary Communities have begun construction on the first home in Sanctuary Village, a Traditional Neighborhood Development (TND) located in the western mountains of North Carolina ...

Sanctuary Village will be a walkable, mixed-use village that will encompass 24 acres of multi-generational living with mansion flats, village houses, tree houses, mountain cottages and a civic/commercial component that will include shops, cafes, book stores, cultural events and community gathering spots a short stroll from homes.

We found this explanation of a Traditional Neighborhood Development:

a comprehensive planning system that includes a variety of housing types and land uses in a defined area. The variety of uses permits educational facilities, civic buildings and commercial establishments to be located within walking distance of private homes...

Haven Custom Homes emphasizes the advantages of building "in an off-site, climate controlled environment where the materials used in your home are protected from the weather."

- Precision construction resulting in straight walls, square corners, fitted windows and flat ceilings.

- Extra reinforcements in bearing walls.

- Move in 16-23 weeks after execution of a contract and your approval of final drawings and finish schedules.

Facts:

-

developers: Tim and Iva Ryan of

Sanctuary Communities

Sanctuary Communities

-

builder:

Haven Custom Homes

Haven Custom Homes

-

designer:

Allison Ramsey Architects (strategic partner)

Allison Ramsey Architects (strategic partner)

- location: "five blocks from Franklin's historic Main Street"

Links:

(Hat tip: Building Systems on October 29, 2008)

In September, Charles Bevier of Building Systems blog mentioned a 2-page spread in the Fall/Winter 2008 issue of Better Homes & Gardens' New Home Magazine (BH&G).

BH&G shines the spotlight on the Gull Island.... The design is one of many Poole has created for ... the Southeast market, homes that are turnkeyed by a network of authorized builders.

The blog post summarizes comments by Bill Murray, general manager of HandCrafted, on the advantages of modular construction:

- less time (120 days full turnkey versus 12 to 18 months for site building the old fashioned way)

- meticulous inspection

- modular units are constructed in the controlled environment and sealed from weather before shipping to the jobsite

The issue will be in newsstands through November.

Clayton homes is holding a showcase of homes this Friday, Saturday & Sunday in Knoxville:

Clayton homes is holding a showcase of homes this Friday, Saturday & Sunday in Knoxville:

This is your opportunity ... to tour dozens of new homes without wasting gas or walking too much. Examine the amenities and style available in today's housing.

Whether you are looking to buy or just looking, it will be the one time this year to see so many houses in one place.

See our earlier post for more details on the company and their previous showcase.

According to their website, the following homes will be on display in Knoxville:

| 4 BR, 2 Bath | Size | ||

|---|---|---|---|

| Fireside II | 2,048 sf | ||

| 3 BR, 2 Bath | Size | ||

| Avondale Marquis | 1,848 sf | ||

| Avondale | 2,048 sf | ||

| Blazer | 1,088 sf | ||

| Blue Ridge | 1,216 sf | ||

| Century | 2,176 sf | ||

| Cumberland Marquis | 1,680 sf | ||

| 2,112 sf | |||

| Elevation Series | 1,344 sf | ||

| 1,568 sf | |||

| Elkmont | 1,456 sf | ||

| 1,680 sf | |||

| Esprit | 1,064 sf | ||

| Excel | 1,216 sf | ||

| Glencrest | 1,792 sf | ||

| Heartlander | 1,568 sf | ||

| 1,680 sf | |||

| 2,128 sf | |||

| Manchester | 1,216 sf | ||

| Mountaineer | 1,280 sf | ||

| Norris | 2,432 sf | ||

| Pinebrook | 1,568 sf | ||

| Pinecrest | 1,680 sf | ||

| River Run - Original | 1,344 sf | ||

| River Run | 1,664 sf | ||

| Worthington | 1,056 sf | ||

| Worthington - Original | 1,568 sf | ||

| 2 BR, 2 Bath | Size | ||

| Community | 1,056 sf | ||

| I-Home, Green House | 1,280 sf | ||

One thing we couldn't tell from their site: which are "modular" (built to local codes) vs. "manufactured" (HUD code).

Clayton Homes is holding a Showcase of Homes at the Triad Center in Greensboro, NC this weekend, October 10-12. From the press release:

Clayton Homes is holding a Showcase of Homes at the Triad Center in Greensboro, NC this weekend, October 10-12. From the press release:

Literally, Clayton Homes constructs a temporary neighborhood in the parking lot of The Triad Center, fully adorned with sidewalks, landscaping, mailboxes and street signs. The Showcase of Homes provides an opportunity for people to tour a variety of manufactured homes and see how dramatically the homes have changed in recent years.

What to expect:

- 20 new, fully-furnished homes on display

- on-the-spot financing

- hot dogs, drinks and popcorn

- $100 gas card drawings each half hour

Clayton CEO Kevin Clayton explains:

Our unofficial motto is 'Best Home -- Best Price' and we take that very seriously.

It has been his mission since taking over as CEO ten years ago to produce manufactured housing that surpasses site-built homes in look, quality, and value.

Clayton Homes produces both "manufactured" and "modular" housing. These terms have a specific meaning in the industry, part of which is covered on their website:

Manufactured Home: Built entirely in the factory under federal code administered by the Department of Housing and Urban Development (HUD).... Covers single or multi-section homes and includes transport to the site and installation.

The industry stopped using the term "mobile home" (and presumably "trailer home") when the HUD code became effective June 15, 1976. Not mentioned: manufactured homes do NOT qualify for a traditional mortgage, in part because the homes tend to lose value every year.

Modular Home: Built to state, local or regional code where the home will be located. System-built homes are transported to sites and installed.

These homes are built to the same standards as conventional "site-built" homes and qualify for a standard mortgage. (In fact they are often somewhat stronger in order to survive transportation and installation by crane.)

At least one home in the Showcase had 2 stories (see above), so it appears that a mix of both types will be shown.

More about Clayton Homes:

- owned by Warren Buffet's Berkshire Hathaway

- recent news coverage outlines how they've avoided the current sub-prime issues

The Christian Science Monitor took a look at modular homes last week, focusing on the green qualities:

This summer, two exhibitions of modular houses – at Chicago’s Museum of Science and Industry (MSI) and New York’s Museum of Modern Art (MoMA) – are putting a spotlight on how off-site building techniques can shrink the carbon footprint of a new house.

The article cites a number of reasons why building in the factory is a good idea:

- finish construction usually takes a few weeks, not months, saving energy by requiring fewer trips to the job site by construction workers

- by building indoors, workers can also more easily make sure that energy-saving features like insulation are carefully and properly installed for maximum effectiveness

- individual home-building companies may not have the resources to keep current on the latest "high-performance building" techniques ... but modular homes can have state-of-the-art environmental design built into them at the factory

The companies mentioned in the article:

-

KieranTimberlake Associates

KieranTimberlake Associates

-

Michelle Kaufmann Designs

Michelle Kaufmann Designs

-

HOM Escape in Style

HOM Escape in Style

- Envision Prefab

- Cardinal Homes

Read the complete article for details.

The Seattle Times reported a few weeks back on an attempt by Unico Properties to bring affordable housing to Seattle:

Several years ago, Unico lost some good downtown office tenants to outlying locations. Sperling says that when he asked the companies why they were moving, they told him most of their employees spent too much time commuting and couldn't afford to live in Seattle.

So, Unico turned to modular construction:

The company retained architectural firms Mithun and HyBrid to explore whether units could be built economically that might appeal to the design, environmental and technological tastes of young urbanites.

The result: the two Inhabit prototypes. The wood-frame units were built in a factory in Burlington, Skagit County, trucked to Seattle, and lifted by crane onto the plaza at the base of Unico's Rainier Tower.

For reference: Mithun, HyBrid Architecture.

The savings?

[The Inhabit units cost] 15 percent less than a conventional project.... [and] the prototypes were built in just three weeks. Units could be put together while other work is going on at the site, and neighbors wouldn't experience as much disruption.

Features of the units include:

- 480 - 675 sf

- studio - 1 bedroom

- 62 units total

- floor-to-ceiling windows, a "green" roof to reduce stormwater runoff

Our previous coverage of prefabs being used for similar high-density developments:

-

the KT2 from the new partnership between

KieranTimberlake and

KieranTimberlake and  LivingHomes

LivingHomes

- an mkLoft development in Denver

- a prefab hotel in London

(Hattip: Jetson Green)

We've previously mentioned Mississippi's Safeway Homes in regards to their strength and affordability. The Sun Herald ("Southern Mississippi's Newspaper") explains further:

Modular homes built in north Mississippi are the first in this state to receive a Fortified Home designation that qualifies the owner for...insurance discounts once the home is properly installed.

"The desire was to build a home that was very strong, but also very low-cost to maintain," said Dan Hobbs, CEO of Safeway Homes in Lexington, Miss. "The whole purpose was to build excellent quality work-force housing. It's cost-efficient housing."

Some specifics about how the Fortified Home program works:

Safeway Homes are designed to withstand 150-mph winds. While the design has received Fortified Home approval, the designation is awarded only after certified personnel have completed foundation and final inspections to ensure each home is properly and permanently anchored, and meets elevation requirements.

To learn more about the "Fortified...for safer living®" program, visit the Institute for Business & Home Safety site. Read the full Sun Herald article for more details on Safeway Home's designation.

Because we couldn't be at Dwell on Design, we sent out some emails to see what attendees had to say. From Jonathan Davis at  pieceHomes:

pieceHomes:

Dwell was a fantastic event, the pieceHomes booth was constantly busy with a stream of very interested, knowledgeable attendees. We launched two new homes along with our new line, extraPieces: modern, green, modular additions for existing homes.

A bit more about the two new homes:

...the Flat Wrap, another in the Wrap series, is a 1,765sf 3 bedroom one story home with expansive glazed walls allow for true indoor/outdoor living. The 1,900sf three story loft Cube House can be used for urban-infill where smaller footprints and higher density are appropriate.

With these two additional models, pieceHomes offers nine standard models, ranging in size from the one bedroom, 320 sf Container House to the 1,900sf Cube House. All of the pieceHomes models, including three custom projects, can be seen in their online brochure (pdf).

The extraPieces concept sounds intriguing:

extraPieces™ provide the extra space needed without having to build a whole new home. Add a family room or a master suite to an existing home, or build a new garage and studio in the backyard. Exterior materials can be customized to complement the finish of the existing home. Interiors can also be customized to meet particular needs and conditions, such as adding a kitchen and full bath to turn eP: studio into a guesthouse. Each of the extraPieces™ uses the same palate of green materials, energy efficient technologies and sustainable construction practices as the new homes by pieceHomes®.

The extraPieces range includes studio, master suite, and extension modules. This product is the first I've seen that offers such prefab solutions specifically for adding a room to your existing home. If they can match a traditional look, perhaps it could be Scott's prefab kitchen?

Back in March, Maryland's Gazette.net reported:

Amid today’s gloom and doom in the housing industry, Vince and Stephanie Scuderi are happy — finally — to talk about building their dream home.They chose a modular home design, an alternative construction method that can save time and money....

The house was together within hours, with all the major workings in place, including framing, drywall, roofing, plumbing, electrical wiring, cabinetry and trim.

‘‘The only problem sometimes raised by the homeowner is that they see it assembled in one or two days, then wonder why it takes another 90 to 120 days to finish,” Dean said. After assembly, much work remains, including well, septic and other utility hookups, porches and decks, driveways and landscaping.

Manufacturer: North American Housing Corp.

The full article has more details and images.

This is a great video from New England's NECN:

A little context:

One year ago, the Lee family was unhappy with their home.... They decided to take their old house down to the ground and build a modular home on the land....The Lees ordered their modular home from a Pennsylvania company. They went modular not because of money, but because of time. The house was assembled like a puzzle - piece by piece.

Each box was about 85% complete on the inside when it was put together....

Modular was clearly the way to go.

Also featured: Sean Sweeney of Heritage Modular.

The Marmol Radziner Prefab blog wrote about the installation of a new home in California. Check out the post for pictures, including the vibrant blue denim insulation seen above.

greenbuildingsNYC discussed Modular Homes, Inc.:

...an Edison, New Jersey-based custom modular home builder that will break ground in April on what it hopes will be a LEED-certified model home in Robbinsville, New Jersey....

Inhabitat's Prefab Friday covered the ABŌD affordable prefab we saw last week.

Low Impact Living interviewed the folks at pieceHomes:

affordability is key. A lot of companies are selling their factory-built work at $400-500/square foot—and they are gorgeous, but very expensive. Our goal is to produce some homes at the $200/sq foot level….we’d prefer to sell more smaller, affordable homes to more clients than a big, expensive home to a really wealthy client...We are working on several homes now….the first one is a custom design. It’s called Rindge. It started off as a conventionally built house. But we realized we could build it in modules with some minor changes to the structural engineering. We realized we could save money and time going that way.

CubeMe covered Camp Smull by  Resolution: 4 Architecture.

Resolution: 4 Architecture.

Materialicio.us discussed the pinc house sport, from Pinc House, a company involved in the Some Assembly Required exhibition we've mentioned previously.

Jetson Green loves the Rapson Greenbelt, mentioned last week.

Inhabitat's Prefab Friday featured the  Magic Box.

Magic Box.

Treehugger looked at a unique prefab:

When your hard drive is full you can plug in another, because they are all designed to be modular and interchangeable. Why shouldn't houses work that way?

architecture.MNP found a cool Danish design:

Designed by Danish firm ONV Architects, the home is a modular [really?] prefab that is both customizable and [supposedly] affordable.Personally, I’m a huge fan of the overall form...

Royal Homes is a major manufacturer of modular homes in Canada. Back in 2005, the company commissioned

Royal Homes is a major manufacturer of modular homes in Canada. Back in 2005, the company commissioned  Kohn Shnier Architects to design the

Kohn Shnier Architects to design the  Royal Q modular:

Royal Q modular:

...six hundred and twenty square feet of efficient, modern design with two bedrooms, tons of storage, all of the necessities and a few of the niceties of life...We will deliver and install in most of Ontario and Michigan, as long as there is a road big enough for our trucks and crane....

Royal Homes completed construction on the larger  Royal Q Muskoka (pictured above) in July of last year. From Treehugger:

Royal Q Muskoka (pictured above) in July of last year. From Treehugger:

The building is essentially a sixteen foot deep wall; ... the maximum width that can go down the road, and Martin Kohn took advantage of this to create the thin, long structure....The terrain is rock, and quite steep. It was disturbed as little as possible, and tree removal was minimized. Because of the difference in grade, Kohn placed the living areas upstairs and the bedrooms below; this way one can change after swimming and then go upstairs to the living areas. One enters by crossing a long bridge from the parking area to the house.

The  m-house is another small prefab home from the UK (we mentioned the home back in September):

m-house is another small prefab home from the UK (we mentioned the home back in September):

...over 1000 sqft of beautifully designed and detailed contemporary house or office. It is entirely manufactured under controlled factory conditions, which guarantees both quality of build and delivery time. m-house arrives in two pieces, each 3m (10' approx) wide, which are then joined together on site, which takes about a day. It comes completely fitted-out and ready for you to move into immediately, and delivery is 12 weeks after order.

Features include:

under floor heating throughout (electric or gas)

solid fuel stove for cosy nights in front of the fire

fitted kitchen with loads of worksurface and storage

fridge, freezer, hob, oven and dishwasher (all Neff in Europe)

utility/ drying room with a washing machine with a decent spin speed

tiled bathroom with nice sanitaryware and a mains pressure shower

big double-ended steel bath with a view out of the window

kingsize bed decks with storage below and big shelves for books

fitted wardrobes with mirrors inside the doors

nice wool bedroom carpets

For some great images of the m-house, check out Ken Sparkes' flickr photostream. And watch this video of the designer from the BBC.

Zenkaya is a prefab from South Africa:

Zenkaya is a prefab from South Africa:

The Zenkaya is delivered completed, ready to live in, to your site right on the back of a flat bed truck.Zenkaya is for the discerning people who value things differently. Those who appreciate their time and don’t want to spend that unforeseen time and energy to control and manage the construction and design process, especially when it is a far away place.

....

Zenkaya design was based on core sustainable principles. To start with, well proportioned rooms, efficient use of spaces and standard size materials were identified and drawn....

The wall panels feature Chromadek (coated metal) on the outside and either polystyrene or OSB (oriented strand board) on the inside.

In form, the Zenkaya models remind me of the concrete  perrinepod.

perrinepod.

Last year, Apartment Therapy New York called the homes "stunning."

materialicio.us said:

I love the fabulous ZENKAYA as much as anyone else.

[SPACEOUTLOUD] shared photos of the homes on display at a show in Cape Town.

Zenkaya models range from 86 sf to 790 sf:

Santa Monica-based Minarc has a (minimal) new website for their M3house.

We first encountered Minarc last April. Treehugger covered them again in July:

We admired the Minarc house by Tryggvi Thorsteinsson and Erla Dögg Ingjaldsdóttir when it was in Dwell; now we learn that they are offering it in a prefab version. The designers...have wanted to design a high-tech modern home that only used materials "in their most organic form and that used recycled materials wherever possible."...They are offering three modular versions built from 2x6 walls, lots of insulation and radiant flooring.

land+living shared several images of a non-prefab prototype from a tour last year. The Minarc brochure (pdf) released at the time explained their  eBOX series 05. It looks like the M3house will be quite different.

eBOX series 05. It looks like the M3house will be quite different.

We look forward to more details on the new home. The image above is the only thing on the new site; what a tease!

We covered many informative websites on prefab and modular homes last year. A few of our favorite posts:

In May, we found the

LV Series Yahoo! Group, a great resource on

LV Series Yahoo! Group, a great resource on  Rocio Romero's

Rocio Romero's  LV Series homes

LV Series homes

We wrote about

Nashville Modern Prefab in June. The plan: to build a Hive Modular home. Sadly, it looks like

Nashville Modern Prefab in June. The plan: to build a Hive Modular home. Sadly, it looks like  work has stalled.

work has stalled.

Shedworking entered our radar at the end of June. The blog is a great source of information on small prefab homes.

Shedworking entered our radar at the end of June. The blog is a great source of information on small prefab homes.

We love

A Prefab Project, which tracks the progress of a

A Prefab Project, which tracks the progress of a  Resolution: 4 Architecture home in West Virginia. In July, we watched the home being delivered.

Resolution: 4 Architecture home in West Virginia. In July, we watched the home being delivered.

Also in July:

Hive Modular started a

Hive Modular started a  blog.

blog.

Sears Homes were some of the earliest prefabs. We were excited when we found a great resource on the homes: the

Sears Archives.

Sears Archives.

I'd forgotten about this one: we covered a great Flickr set of a

Flatpack House going up. Now the home is

Flatpack House going up. Now the home is  much more complete.

much more complete.

In December, we came across

ModularHomeChoice.com. It offers some useful information about building a modular home.

ModularHomeChoice.com. It offers some useful information about building a modular home.

And we saw

Secret Fortress Hideout, a blog all about the construction of an

Secret Fortress Hideout, a blog all about the construction of an  LVL Home.

LVL Home.

Greg LaVardera brings us Letters from Sweden - land of modern, land of prefab:

Greg LaVardera brings us Letters from Sweden - land of modern, land of prefab:

In my previous entry I introduced Scott, my correspondent from Sweden. An American builder relocated to a suburb of Stockholm, he landed in an alternate reality where modern housing was everywhere, commonplace, even dare I say unremarkable. None of the stigmas or resistance we have come to associate with building a modern house were present. Every builder offered solid modern design in the range of homes they sold, and were more than happy to sell you one. On top of this prefabrication techniques were the norm. Sizable portions of the houses Scott saw being built were put together in the factory...

What did Scott find?

"...the majority of new construction is built like this. I would call the house panelized - but it is "way way panelized" and is a total package. The houses come on trucks from rural places in Sweden. The windows are in, the insulation, wiring, wallboard where possible - every thing - the pipes, the wiring systems, the doors, stairs ... everything has been engineered and rationalized to reduce labor, find energy and material economy and work with the method of construction where stuff is pre-assembled as much as possible inside a building and then "erected" or installed on the site under very compressed schedules...."

Read the full post for Greg's comparison to prefab on this side of the pond.

We recently added Modular Today to our sidebar. The site is useful for anyone looking to build a modular home, with information ranging from an expected timeline to a financing guide.

System3, from Austrian designers

System3, from Austrian designers  Oskar Leo Kaufmann and Albert Rüf, will also be showcased in MoMA's Home Delivery: Fabricating the Modern Dwellings show:

Oskar Leo Kaufmann and Albert Rüf, will also be showcased in MoMA's Home Delivery: Fabricating the Modern Dwellings show:

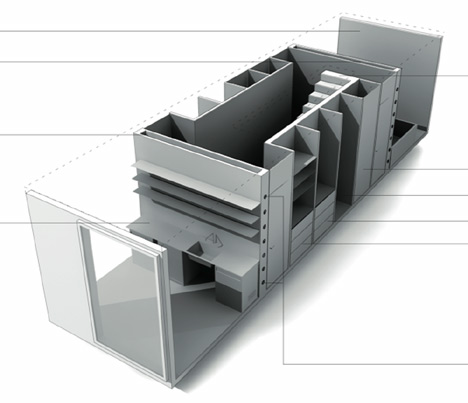

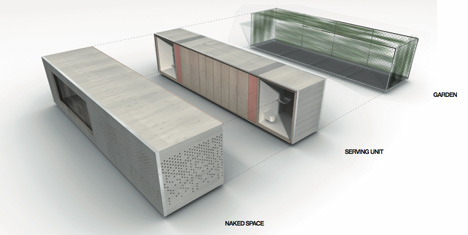

The system is based on the separation of a building into "serving space" and "naked space".The "serving space" is a completely prefabricated serving unit that provides all staircases, kitchens, baths, installations, electricity, heating, and cooling systems for the entire building. The "naked space" (space that is only defined by the placed furniture, such as living or sleeping rooms) is formed by "naked elements": solid slabs of wood...windows, skin. All "naked" elements are also prefabricated and are delivered directly from factory to building site, where everything can be assembled in a few days.

Each unit fits in a shipping container, giving it the characteristic "long and narrow" format. Several units can be placed side by side:

Or stacked:

Overall, an intriguing approach that I can't wait to see realized at MoMA. Oskar Leo Kaufmann and Albert Rüf have been experimenting with prefab since 1996. We'll look at their past work in more depth soon!

G Living commented on the TrailerWrap project:

While the low cost motive behind the introduction of mobile homes in the mid-1900s was a good one, the execution was often aesthetically reprehensible, shoddily constructed and inefficient energy-wise. TrailerWrap set out to take these small, dilapidated (often abandoned) structures and re-fashion them into something exciting and remarkable, yet sustainable and affordable.

Freshome covered the  Perrinepod:

Perrinepod:

a cute prefab home that can be built in just 3 days and withstand everything from earthquakes to cyclones.

The Good Human's Prefab Wednesday showed a prefab development in London that was covered last year on some of the other blogs.

Inhabitat's Prefab Friday featured the Single Hauz, a sort of house-meets-billboard:

...the idea takes shape in such a stylish little form that we can’t help ponder the challenge posed: how much space do you really need and where do you want it?

TreeHugger posted a video of  Adam Kalkin speaking about containers, and looked back at their enthusiasm of three years ago.

Adam Kalkin speaking about containers, and looked back at their enthusiasm of three years ago.

On the heels of the port-a-bach comes news of the iPad, another prefab "bach" (see note below) from New Zealand:

The iPAD is a true kitset bach designed to covers a range of options; it could be a one bedroom holiday home, secondary dwelling, granny flat, office, studio or resort unit to name but a few.It can be grouped as a series of pavilions to form larger accommodation if required....

Of particular note is that the iPAD can be either manufactured off-site and easily transported to its final destination, or shipped as a kitset and erected on site by a licensed contractor.

TreeHugger has some thoughts and also mentions the earlier Bachkit.

Bach = "small structures like beach huts or small holiday homes" (from Shedworking)

(Hat tip: Materialicio.us)

More details about the modular homes that are replacing FEMA trailers for Katrina victims:

People will have to apply for the housing and will pay rent in the first year of 20 percent of household income. After that, occupants have the option to buy the homes, and a portion of the rent can be used for a down payment. In addition, the occupants will get help finding mortgages.

I came across ModularHomeChoice.com while perusing some news the other day:

This website is for those interested in purchasing a modular home or those considering one and wishing to learn more about them. I will share my experiences and lessons learned while acting as the general contractor on my modular home in the St. Louis, Missouri area.When researching modular homes, I found a lot of information supplied by builders or sales agents of modular homes. I am trying to add another perspective to that - that of someone purchasing a modular home as well as being heavily involved in the planning and scheduling of the project.

Sections of the site include:

• background information

• a list of modular builders by state

• financing

• lessons learned

• pictures of all stages of the process

The site is barebones, but informative.

Toll roads aren't just annoying to commuters; they can raise the cost of doing business: